The Qualities of Letterpress Paper

by Evan Calkins -Inspired by craftsmanship and the tiny details, the choice of paper is paramount to quality letterpress printing.

An close up at the texture of house paper, Neenah Cotton

An close up at the texture of house paper, Neenah Cotton

In the world of Dwight Schrute, paper is squarely at the butt end of the joke. Dunder Mifflin, the fictional paper vendor from NBC's The Office, has been conceived as the setting for the most vapid of industries. What could be more uninspiring than a cubical filled office space selling copy paper to other soul-sucking companies?

We wholeheartedly concede to this premise: office paper is quite uninteresting. Nobody has ever Instagrammed their adventure to the local Staples to pick up a ream of 20 lb. copy paper. There are no vintage photo filters that can enhance that experience.

Luckily for us, our paper doesn't come from the Dunder Mifflin warehouse. In the world of letterpress printing, the quality of paper is held in as much esteem as the quality of printing. In fact, the two go hand in hand. The paper we choose facilitates the qualities that we appreciate most about letterpress printing - the visual and tactile impression into the paper.

It's worth noting that there's a wide range of projects that demand many different types of paper. For example, some letterpress printers specialize in large format posters and broadsides which can require a particular type of paper; however, because we specialize in small stationery items like calling cards, business cards, and notecards, we will be covering the qualities that are best suited for those applications.

Here is a brief crash course in the attributes we love most about letterpress worthy papers:

100% Cotton "Tree-Free" Paper

Cotton paper and letterpress printing go together like The Dude and a White Russian. A vast majority of our projects are printed on 100% cotton papers for several reasons:

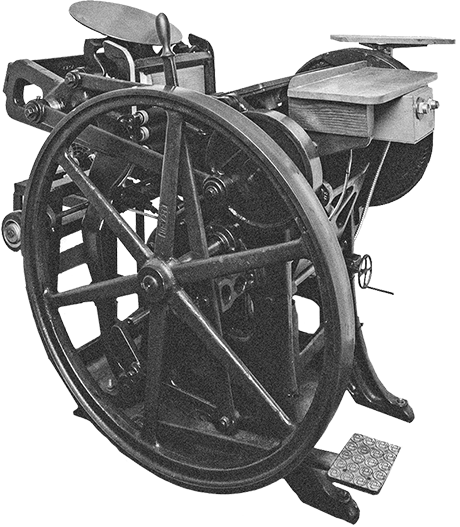

Cotton paper is extremely durable. The long fibers in cotton make a soft paper that can hold up to the demands of a platen letterpress. At hundreds of pounds per inch, the pressure produced by a letterpress is immense and the thick cotton stock handles it beautifully. Fun fact: The U.S. paper currency is made up of 75% cotton for its durability and longevity.

Cotton paper is beautiful. Most cotton letterpress papers have a great toothy texture that has a striking contrast to the crisp letterpress impression. Although cotton papers can be made smooth during the papermaking process, we love papers with a raw organic texture that is produced from a less invasive, natural drying process.

Cotton paper is eco-friendly. Many 100% cotton letterpress papers are not only tree-free but are created using high-quality cotton nters that have been discarded from the textile industry. Sustainably speaking, these processes have an even lower environmental impact than recycled papers.

The uncoated finish of 100% cotton paper produces a printed ink that is matte.

The uncoated finish of 100% cotton paper produces a printed ink that is matte.

Thick Paper

Because most of us love the look of a letterpress impression, the thickness of the paper needs to accommodate the impression depth. For this reason, most of our projects are printed on cover weights - which are paper weights traditionally created for book covers (as opposed to the inner pages of a book). Because letterpress paper is less dense by volume, it tends to be even thicker than other paper of the same weight.

As it turns out, most people love a thick card regardless of the printing method. So, a substantial weighted cotton paper does well to reinforce the premium nature of a letterpress printed business card or note card. Thick stock and letterpress are most often joined at the hip.

Paper Colors

Most of the high-quality cotton letterpress papers come in various shades of white ranging from a bright white to a cream or Ecru white. We generally stick to printing on white or light papers because letterpress printing excels at printing darker inks on lighter papers. The inverse is meant more for conventional printing methods that can spread more ink over the surface of the paper in one pass. Letterpress inks aren't generally opaque enough to show up well on black or dark stock.

The Colophon Calling Card, letterpress printed on Colorplan Citrine

The Colophon Calling Card, letterpress printed on Colorplan Citrine

Handmade Papers

Letterpress printing has the great advantage of accommodating papers of widely varying thicknesses and textures. This is especially true with handmade paper. Handmade papers are extremely variable and exaggerated in size and texture. Modern printing methods can't accommodate their unpredictable variations. Because we feed our letterpresses by hand, the variation can be overcome and the letterpress impression on a handmade paper can be very striking!

A handmade paper with deckled edges.

A handmade paper with deckled edges.

Our House Papers

Most print shops have their favorite house stock they recommend for most projects. Our current house stock is Neenah Cotton, which we use for 90% of the work we do. Neenah Cotton is specifically made with letterpress printing in mind and carries all the benefits of a 100% cotton paper. It's reliable, durable, and takes one of the best letterpress impressions that we've seen. Its thicker duplexed 220# weight is great for double-sided business cards, or anyone desiring a substantially thick card or invite. Neenah also provides a matching thinner text weight for letterheads, writing stationery and envelopes.

For colored papers, we most often recommend the many colors of Colorplan, which is an all wood pulp paper (as opposed to cotton) and is much more rigid and dense (We use Colorplan for our Colophon Card). Because it's more compressed, the impression depth is considerably more subtle.

The paper we use is just as intentional as any other ingredient in our process. Understandably, we romanticize about the printmaking process, the old letterpress machines, and craftsmanship that's involved in producing letterpress printed work. Sometimes, the paper flies under the radar and doesn't get the credit it deserves. At Hoban Cards, we're continually excited to experiment with new papers and sing the praise of the specialty paper industry.

Thanks for Reading!

We not only love writing about letterpress, typography, and design – we're printers ourselves! We've chosen to carry on the tradition of letterpress printing by offering beautifully pre-designed cards at affordable prices.