Meet Our Letterpresses

by Evan Calkins -Over the last 10 years we've collected 4 letterpresses, ranging in manufacturing years from 1902-1970. Each press has a special use in our shop and a unique story of how we acquired them.

Over one hundred years of ink and grease layering the cast iron surface of our still functional 1000+ pound letterpress printing machines exemplifies the adage “they don’t make things like they used to.” As much as this is true, it’s also equally as obvious WHY they don’t make things like they used to. These printing machines are clumsy, seemingly immovable, inefficient, cumbersome behemoths of a much older era. Their practicality can barely be sniffed out - especially in a world where print is already of such little value compared to the obvious alternative. It would also be perfectly reasonable to assume these machines, apart from their mere historical significance, are utterly useless. Even further, perhaps they’d be worth more as scrap metal at the local salvage yard. This can be argued, especially since so many of them have seen this very fate.

Despite the dismal prognosis above, for our tiny shop, these machines are both undeniably beautiful and fantastically practical. They were originally called “jobbing” presses and were designed to produce relatively high quantities (for the era) of smaller sized prints in a short amount of time. As opposed to the older style (think Gutenberg) printing presses that were entirely hand operated, these platen-style presses uses the inertia of a heavy flywheel to turn the press over. Mechanisms like gears, cogs and pawls allowed the motion to ink the letterpress form and produce a clamshell force that crashes the inked type onto the paper. The sound is undeniably therapeutic, like a giant cast iron clock on our shop floor.

Here's a short introduction of our current lineup:

1902 10x15 Chandler & Price – Old Style

This letterpress was the first press I acquired back in 2010. It was found in the basement of a print shop in my hometown, Centralia, Washington. With the help of family and friends, we were able to dismantle the press and haul it, piece by piece (and dangerously), out of the basement. After thoroughly cleaning, we reassembled and oiled the press. After a shiny new set of rubber rollers, I was able to start my letterpress journey on this 1500lb piece of steel and cast iron, working out of my home garage.

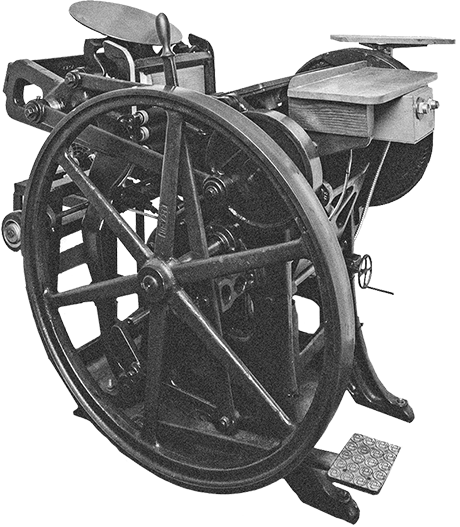

1945 8x12 Chandler & Price – New Style

This beautiful, late production letterpress was my fourth letterpress. I found it in a Washington State Surplus auction and won the bid. According to a government marking adhered to the press, this press was utilized in some capacity in the Washington State Correctional facilities. It's manufacturing date was in 1945, which makes it one of the last Chandler and Price platen presses of its kind ever made. It's "New Style" moniker groups it together with later made platen presses that have straight flywheel spokes, as opposed to the more ornate curved spokes of the old style press. If you've ever ordered calling cards from us, it's very likely they were printed on this press.

1914 8x12 Chandler & Price – Old Style

We call this the little brother to our larger 10x15 press because they are almost identical. The smaller 8x12 bed size of this letterpress means that it weighs almost 40% less. We found this machine from a modern print shop in Portland Oregon that was liquidating some unused equipment. This press was most likely used for creasing and scoring as evidenced from the subtle perforation markings on the bed. Many platen presses like these were retired from actual printing in their later life and relegated to die cutting, creasing or numbering as larger modern press pushed them aside.

1970 Heidelberg (Windmill) T-Platen

I often refer to our Windmill as the Cadillac of Letterpresses. Although, maybe a Mercedes is more accurate as this was manufactured in Heidelberg Germany in the early 70s. Heidelberg T Platen was the technical name, but the community quickly adopted the "Windmill" nickname because the gripper bars resemble a windmill motion. Unlike the older letterpresses, the Windmill was originally made to run with an electric motor instead of a foot treadle. Among countless other improvements, they had a "sucker bar" that automatically feeds paper into the grippers. We use the Windmill for larger items like invitations, note cards, and menus.

Thanks for Reading!

We not only love writing about letterpress, typography, and design – we're printers ourselves! We've chosen to carry on the tradition of letterpress printing by offering beautifully pre-designed cards at affordable prices.